Restoration: Bringing Your Boat Back to Life

A Step-by-Step Guide to Gelcoat and Fiberglass Restoration

The restoration of a gelcoat can seem daunting, but by breaking it down into manageable steps, you can achieve professional-grade results. Below is a general process for restoring a gelcoat surface. This process is designed to be a guide, as the specific products and techniques may vary depending on the condition of your boat's surface.

Brought to you by SG Marine.

-

The first and most crucial step is to get the surface clean. For heavily oxidized boats, we recommend a degreasing wash to cut through years of grime and old oxidation. For a newer boat, a degreasing wash is still a good idea to remove any residual mold release wax, which can interfere with the next steps. Avoid using soaps that will leave a silicone or paraffin layer if you are going to compound afterward.

-

The goal is to remove the layer of oxidized gelcoat. This may require sanding if the oxidation is severe. For heavy oxidation, we often start with an 800-1200 grit sandpaper, followed by a cutting compound. After compounding, you'll need to remove the swirls and holograms left behind.

A medium-cut and/or polishing compound with a rotary or dual-action (DA) polisher and the appropriate pad will smooth out the surface, bringing back that deep, reflective shine.

-

After compounding and polishing, there will be dust and product residue on the surface. A thorough wash with a proper boat soap is needed to remove these contaminants, preparing the surface for the final protective coating. Again, we would recommend a non-silicone or paraffin soap.

-

This is a critical step that many people overlook. A final wipe-down with a solvent like 91% isopropyl alcohol is necessary to remove any lingering oils or contaminants that a simple wash might miss.

Use a clean microfiber or lint-free cloth and let the solvent flash off completely before moving on. This ensures a clean, bare surface for the coating to bond to.

-

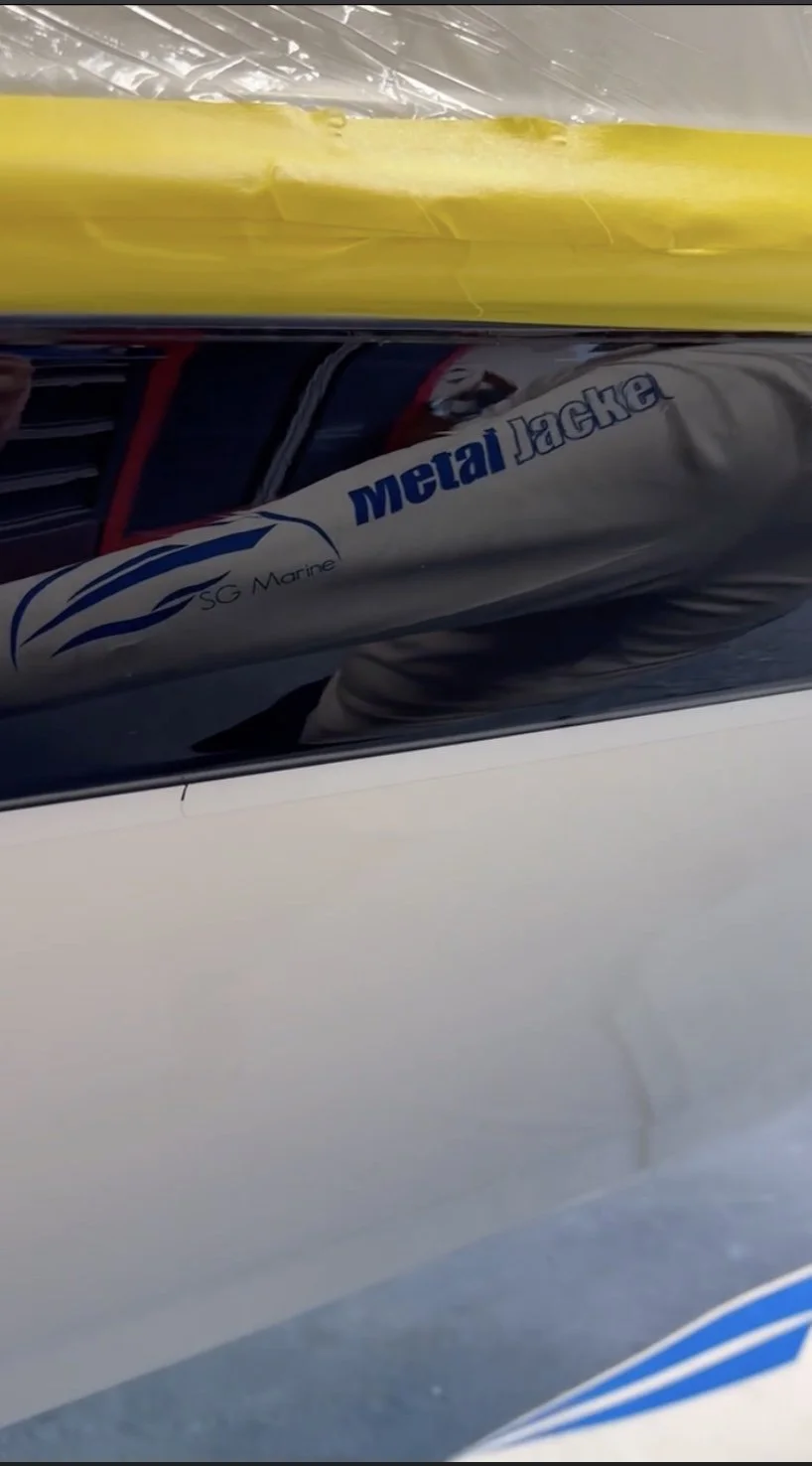

Now that your boat's gelcoat is restored and the surface is perfectly prepped, it's time to protect it. Our MetalJacket FG coating is designed specifically for this purpose. It creates a durable, long-lasting barrier that resists oxidation, UV damage, and chemical staining.**

-

If you're looking for protection below the waterline only, the HullJacket is what we recommend. It is a spray-only product by using an HVLP gun at low pressure using a 1.2mm nozzle tip.

Photos 1-2: These two are examples of sanding.

Photos 3-4: These two are examples of compounding with two different pads.

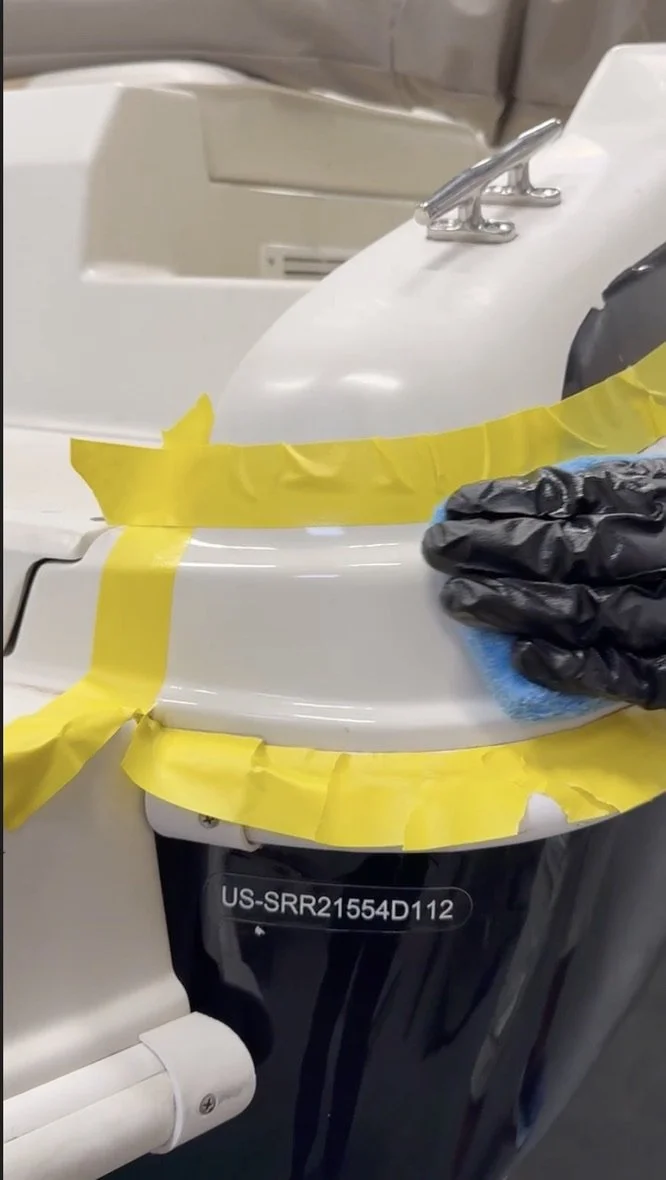

Photo 5: The spray is the application method of the HullJacket. The wipe on with the blue microfiber pad is for the MetalJacket FG.

Photos 6-8: These 3 are to show off the reflection of our product and the final look outside already coated.